The installation of natural stone must be performed by an experienced installation contractor with care

given to

the protection of the stone until construction is complete. We recommend requiring your contractor to

make a

“mockup” board to test grout, sealers, and maintenance products prior to the commencement of project

installation. Be sure that the stone is protected from construction dirt, dust and foot trafic, until

the entire

project is complete.

1. Maintenance Notes

Indian natural stone is renowned for its unique beauty and durability. However, to maintain its appearance and strength over time, it requires special attention. Whether used for flooring, pavement, or cladding, it is important to take regular care to preserve the material's durability and visual appeal.

Regular Sweeping or Vacuuming: Use a soft-bristled broom or vacuum cleaner with a brush attachment to remove loose particles and dirt, preventing scratches and abrasions.

Appropriate Sealant : It is important to choose a high-quality penetrating sealer that is specifically formulated for Indian stone. To ensure that the sealer is compatible with the stone and effective, it is recommended to first test it on a small, inconspicuous area. The sealer should be applied evenly using a clean, lint-free cloth, brush, or roller as instructed by the manufacturer. Allow the sealer to fully permeate the stone and dry completely before using the surface.

Regular Inspection : It is important to regularly inspect the stone surface for signs of wear, damage, or degradation. Any issues should be addressed promptly to prevent further damage.

2. Product Notes

Understanding and appreciating color variations are important in natural stone projects for creating a unified and visually pleasing design. By mastering the art of adaptation and implementing tactics for dealing with these variances, such as combining materials and choosing complimentary hues, you can improve the attractiveness of your space and create a harmonious setting that highlights the distinctive qualities of natural stone. From the quarry to the installation, overcoming color differences in natural stone projects takes meticulous preparation and attention to detail to provide a spectacular end product that truly stands out.

Quarried products hold a distinctive allure due to their natural beauty and individuality, making them a popular choice for interior and exterior design projects. This is a quarried product, color, and stone characteristics, such as veining, will vary within the same piece and totality of the order.

There are many different edge and surface finishes available, please double check to be sure your order is as specified prior to installation.

3. Installation Notes

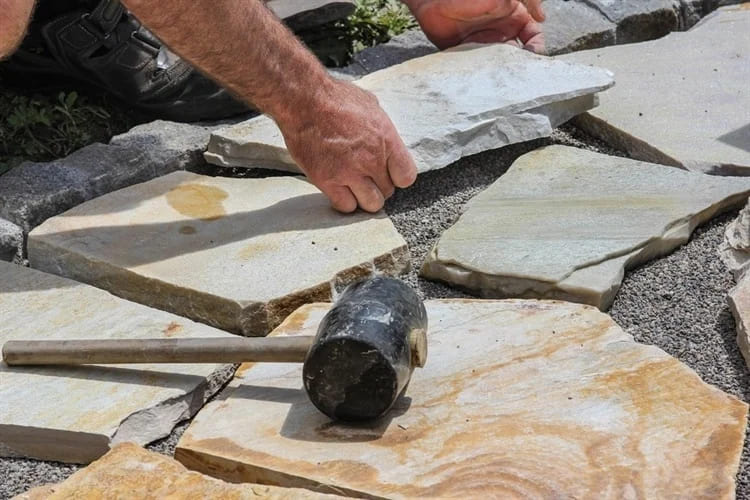

When installing natural stone for flooring, walls, or other applications, it is crucial to consider several factors to ensure a successful and long-lasting installation.

Surface Preparation : Proper surface preparation is crucial to ensure the stone's adherence. It is necessary to clean, dry and remove any debris, dust, oil, grease, or other impurities that may interfere with it.

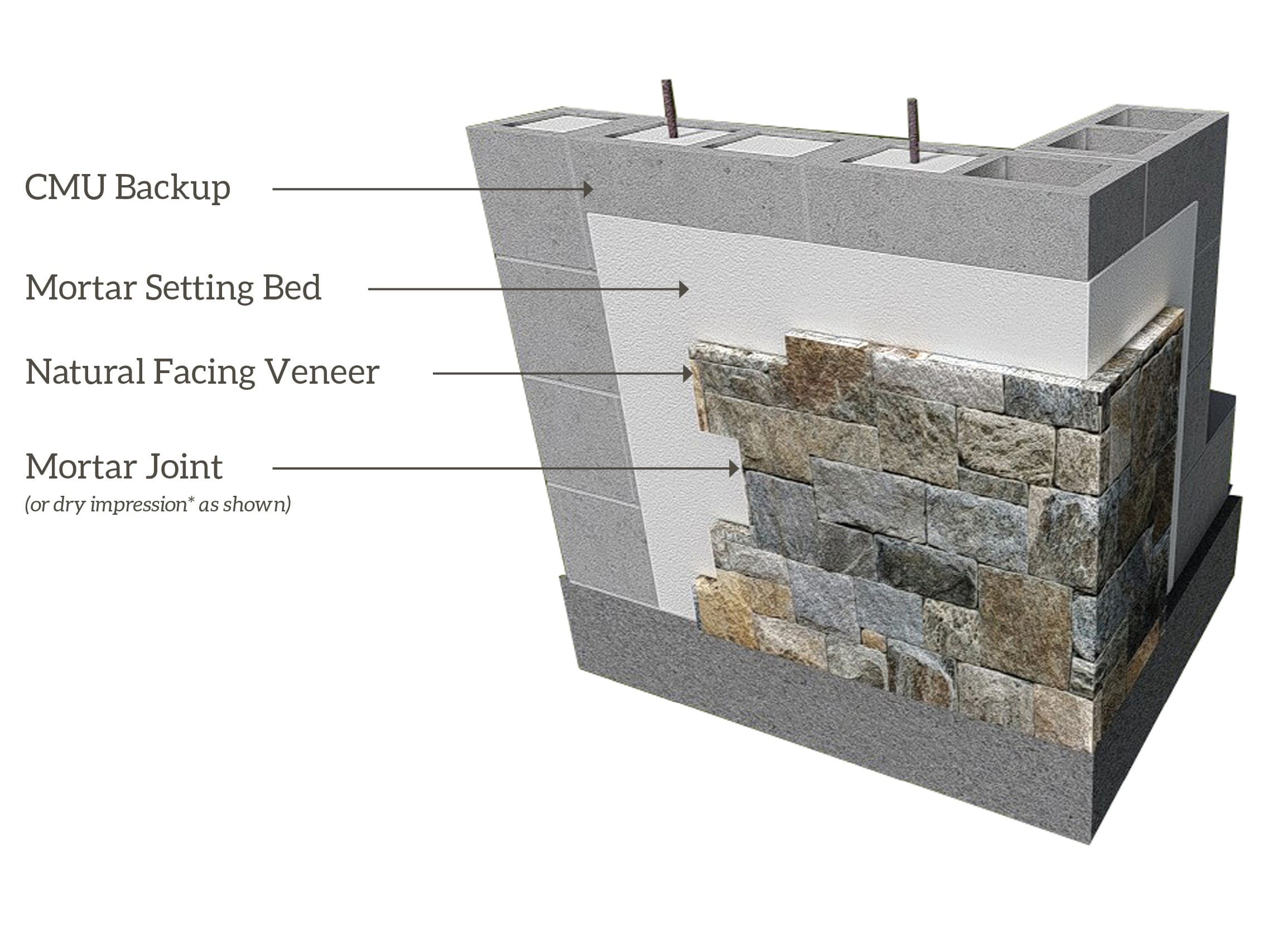

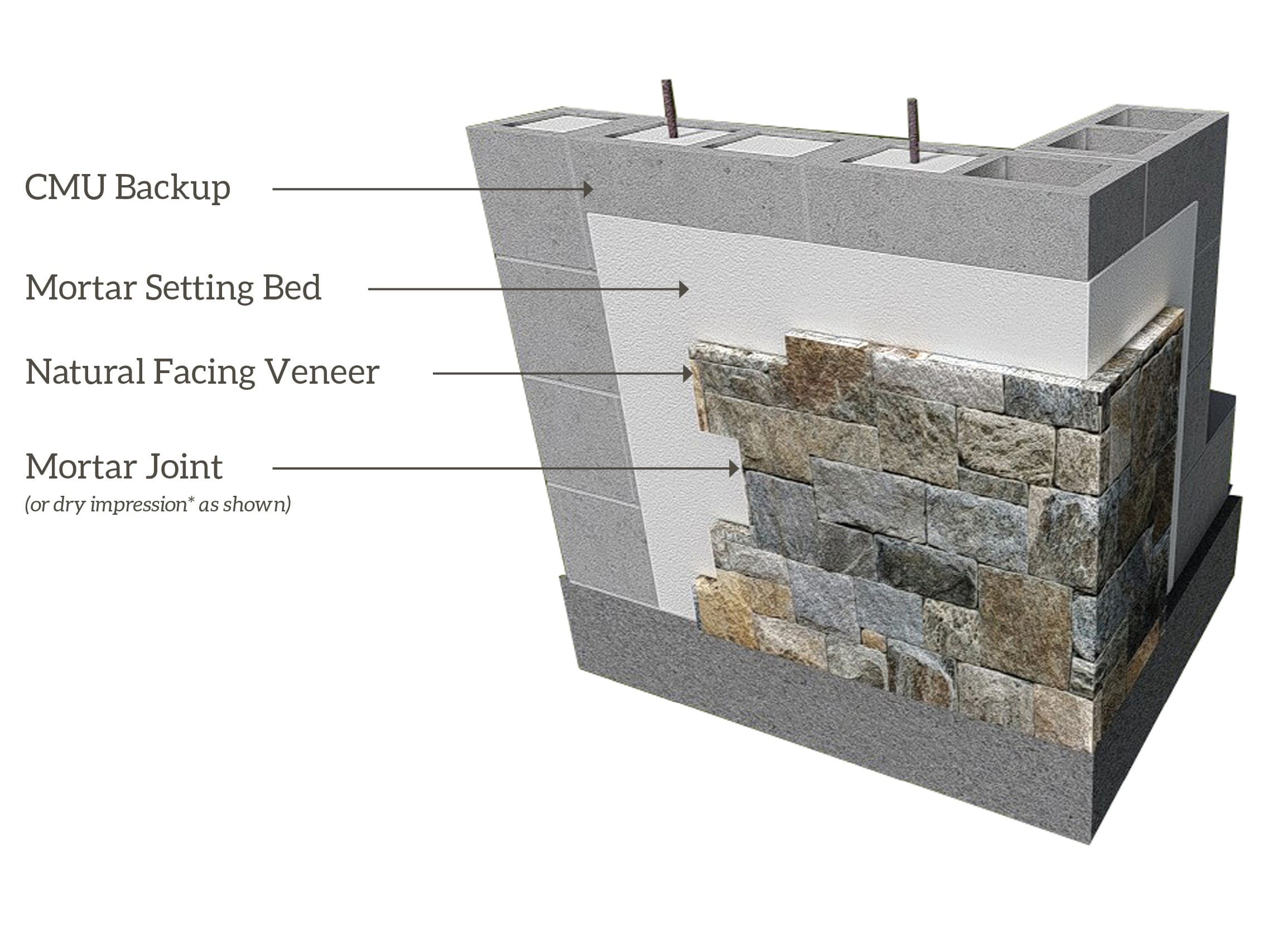

Substrate : The substrate must be structurally stable and able to support the weight of the stone. If required, use an appropriate underlayment or backer board.

Layout : Before installing natural stone tiles or pieces, it is important to plan their placement to ensure a visually balanced and acceptable arrangement, especially if the stone contains natural variances in color, pattern, or texture.

Adhesive : It is important to select an appropriate adhesive or mortar that is suitable for both the natural stone and the substrate. Follow the mixing and application instructions provided by the manufacturer.

Sealing : is important to apply an appropriate sealant to natural stones before and after grouting to prevent stains, dampness, and other damage as many of them are permeable. Make sure to follow the manufacturer's instructions while applying the sealant.